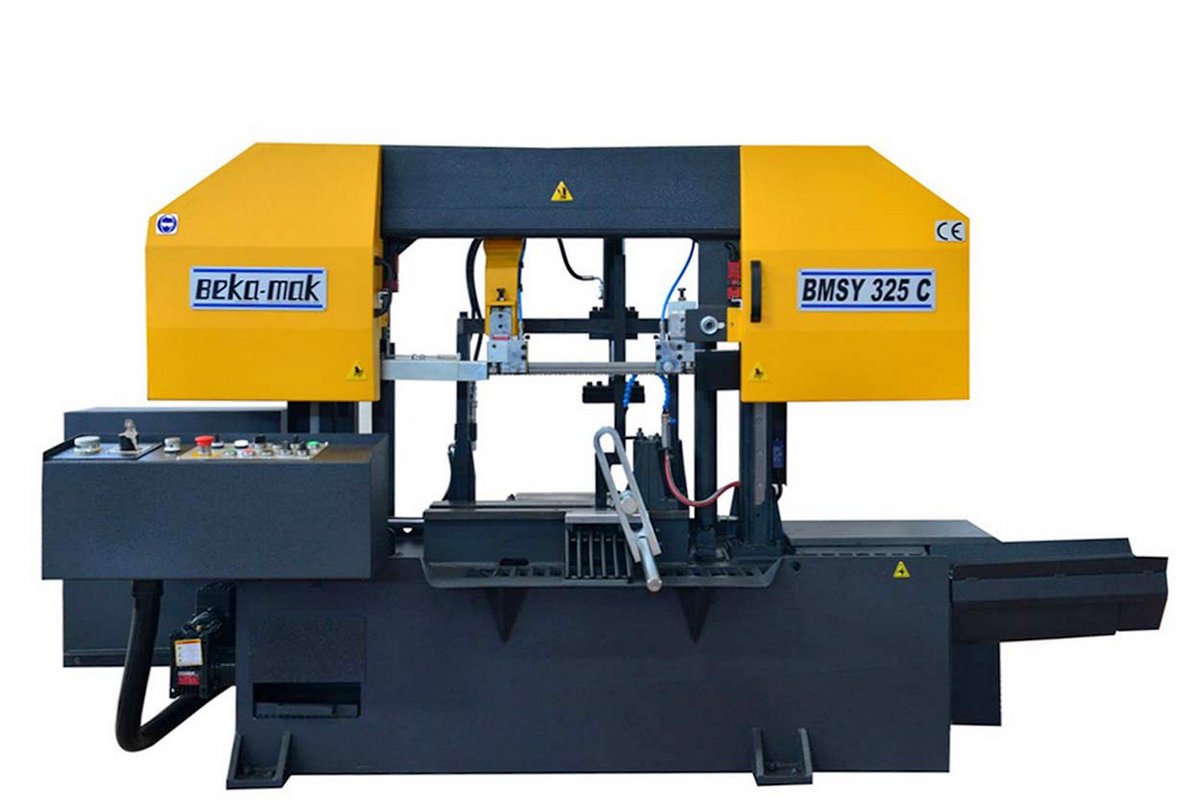

Description

| PARAMETER | UNIT | UNIT |

|---|---|---|

| Round Cutting Capacity | mm | 325 |

| Flat Cutting Capacity | mm | 450 x 325 |

| Square Cutting Capacity | mm | 325 |

| +45° Round Cutting Capacity | mm | 250 |

| +45° Flat Cutting Capacity | mm | 250 x 325 |

| +45° Square Cutting Capacity | mm | 250 |

| Main Drive Motor | kW | 3 |

| Hydraulic Motor | kW | 0,55 |

| Coolant Pump | kW | 0,12 |

| Cutting Speeds | m/min. | 20 – 100 |

| Band Dimensions | mm | 4160x34x1,1 |

| Working Height | mm | 580 |

| Weight | kg | 1010 |

| Length | mm | 2150 |

| Width | mm | 860 |

| Height | mm | 1500 |

The bow is constructed in heavy gauge steel and mounted two chromed and grinding pillars offer a strong rigid sawframe, providing a high degree of accurancy when cutting.

The machines are fitted with a removable coolant tank incorporating a submerged electric coolant pump which supplies coolant to both guide assemblies.

These models can cope with most types of material.

Blade guides with rollers and carbide pads provide precise support for the blade.

Thermal overload and no-volt release are standart feature and the machines automatically switch off at the end of the cut and sawframe is lifted hydraulically up to the adjusted level.

Bi-Metal sawblade and 1,2 meter infeed roller table are supplied as standard.

- 2° Inclined Blade

- Saw Blade 34

- Saw Blade Brash

- Security Switch

- Metarial Limit Shaft

- Pressure Adjustment

- Hydromechnic Blade Tension

- Control Panel

- Optical Height Adjustment

- Coolant Pump

- linear Guides

- Heavy Duty Gearbox

- 1,2 Mt Metarial Roller Table

- ILC Microspray Coolant

- Hydraulic Blade Tension

- 3 Mt Roller Table

- Turn Table

- Lazer Line Pointer

- Multiple Segments

- Split Vice

- Chip Conveyor