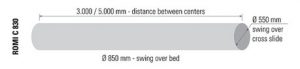

| Technical specifications | ROMI C 830 | |

| Capacity | ||

| Centers height | mm (in) | 435 (17.1) |

| Distance between centers | m (in) | 3.0 / 5.0 (118 / 197) |

| Swing over bed | mm (in) | 850 (33) |

| Swing over cross slide | mm (in) | 550 (22) |

| Cross slide travel (X axis) | mm (in) | 520 (20) |

| Longitudinal carriage travel (Z axis) | mm (in) | 3,020 / 5,020 (119 / 198) |

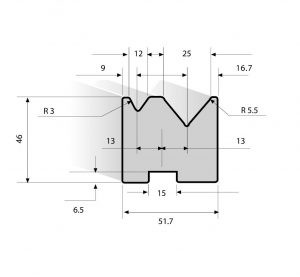

| Bed | ||

| Width | mm (in) | 460 (18.1) |

| Height | mm (in) | 420 (16.5) |

| Headstock | ||

| Spindle nose | ASA | A2-11” A2-15“ |

| Spindle hole diameter | mm (in) | 160 (6.3) 260 (10.2) |

| Transmission system | Geared | |

| Speed ranges | rpm | 1 to 1,000 1 to 550 |

| Range I | 1 to 250 1 to 200 | |

| Range II | 1 to 1,000 1 to 550 | |

| Feeds | ||

| Rapid traverse (Z axis) | m/min (in/min) | 8 (315) (*) / 5 (197) (**) |

| Rapid traverse (X axis) | m/min (in/min) | 8 (315) |

| Manual Tailstock | ||

| Body positioning | Drag trough the table | |

| Quill drive | Manual (std) / Hydraulic (opt) | |

| Maximum quill stroke | mm (in) | 200 (7.9) |

| Quill diameter | mm (in) | 130 (5.1) |

| Quill taper hole | CM | 5 |

| Installed power | ||

| AC Main motor (S6 – 40% rating) | hp / kW | 45 / 33.6 |

| AC Main motor (continuous rating) | kVA | 40 |

| Dimensions and weight (*) | ||

| Floor space required – 3.0 m between centers | m (in) | 7.52 x 3.20 (296 x 126) |

| Floor space required – 5.0 m between centers | m (in) | 9.52 x 3.20 (375 x 126) |

| Approx. net weight – 3.0 m between centers | kg (lbs) | 11,460 (25,265) |

| Approx. net weight – 5.0 m between centers | kg (lbs) | 14.960 (32,980) |

| (*) for 3.0 m between centers (**) for 5.0 m between centers (***) Without chip conveyor | ||