1- ROMI D 1000 HYBRID

ROMI D Series Hybrid Machining Centers combine machining operations and additive manufacturing (3D metallic printing) in a single piece of equipment.

- Materials can be added in the exact amount to achieve the desired profile, and later machined;

- Savings in the use of high-cost materials;

- Low-temperature transmission to the part, avoiding possible thermal cracks;

- Performs engraving and texturing operations;

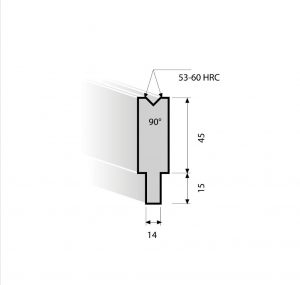

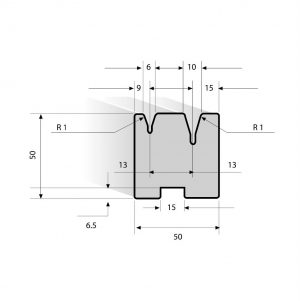

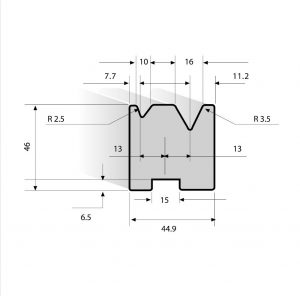

It is possible to add materials of greater resistance in certain areas of greater wear, increasing the durability of the parts or components, as in stamping tools.