| TECHNICAL SPECIFICATIONS | ROMI DCM 620-5F | |

| Vertical headstock | ||

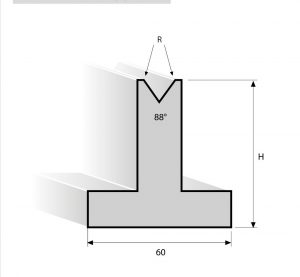

| Spindle taper | ISO | 40 |

| Speed ranges (RPM) | rpm | 10 to 10,000 |

| Feeds | ||

| Rapid traverse (X / Y / Z axes) | m/min (in/min) | 36 (1,417) |

| Max. programmable cutting feed | mm/min (in/min) | 1 to 20,000 (0,04 to 787) |

| Maximum rotation (B and C axes) | rpm | 12 |

| Travels | ||

| X axis travel | mm (in) | 620 (24) |

| Y axis travel | mm (in) | 520 (20) |

| Z axis travel | mm (in) | 460 (18,1) |

| Distance between spindle and table | mm (in) | 150 ~ 610 (5,9 ~ 24) |

| Rotation angle – B axis | degrees | -110 degrees ~ +110 degrees (**) |

| Rotation angle – C axis | degrees | 360 degrees |

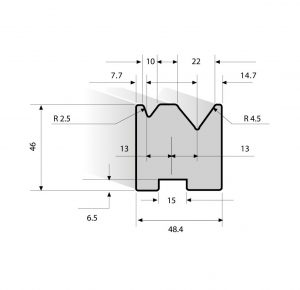

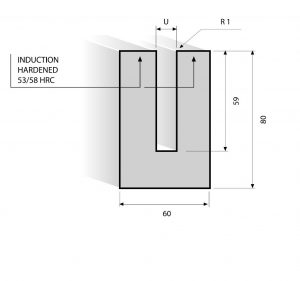

| Rotary table | ||

| Table surface | mm (in) | 600 (24) x 600 (24) |

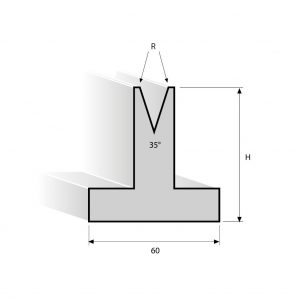

| Number of T-slots | un | 5 |

| T-slot width x distance | mm (in) | 18 x 100 (0,71 x 3,9) |

| Central guide hole | mm (in) | Ø 60 (2,4) H7 |

| Max. piece dimension on table | mm (in) | Ø 520 (20) x 330 (13) height |

| Allowed weight | kg (lbs) | 300 (660) |

| Automatic tool changer | ||

| Tool capacity | 30 | |

| Tool max. diameter | mm (in) | 76 (3) |

| Max. tool diameter when adjacent stations are empty | mm (in) | 127 (5) |

| Max. tool length | mm (in) | 250 (9,8) |

| Max. tool weight | kg (lbs) | 7 (15) |

| Max. weight on magazine | kg (lbs) | 160 (353) |

| Tool holder type | type | BT / BBT 40 |

| Power | ||

| Main motor AC (S6 – 40% – 10 min. rating) | hp / kW | 24 / 18 |

| Main motor AC (continuous rating) | hp / kW | 16/12 |

| Total installed power | kVa | 50 |

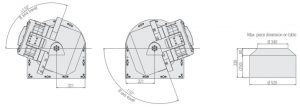

| Dimensions and weight (*) | ||

| Height | mm (in) | 2,873 (113) |

| Floor space required (front x side) | mm (in) | 4,167 x 3,400 (164 x 134) |

| Net weight | kg (lbs) | 9,200 (20,300) |

| (*) Without chip conveyor (**) Machines equipped with tool preset the angle becomes +80 degrees. | ||