| Technical specifications | ROMI GL 170G | |

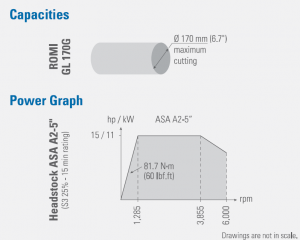

| Capacity | ||

| Swing over Z axis cover | mm (in) | 410 (16.1) |

| Max. cutting diameter | mm (in) | 170 (6.7) |

| Max. cutting length (between centers) | mm (in) | |

| Travel (X axis) | mm (in) | 465 (18.3) |

| Travel (Z axis) | mm (in) | 400 (15.7) |

| Headstock | ||

| Spindle nase | ASA | A 2-5″ |

| Spindle thru-hole | mm (in) | 60 (2.4) |

| Bar capacity (diameter) | mm (in) | 51 (2) |

| Speed range | rpm | 6 to 6,000 |

| Feeds | ||

| Rapid traverse (X axis) | m/min (in/min) | 36 (1,417) |

| Rapid traverse (Z axis) | m/min (in/min) | 30 (1,181) |

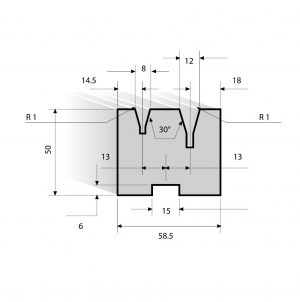

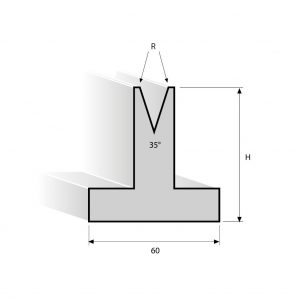

| Turret | ||

| Saddle surface (gang tools) | mm (in) | 180 x 600 (7.1 x 24) |

| Number of T-slots | 3 | |

| Number of tools/stations | un | |

| Tool holder type | gang tools | |

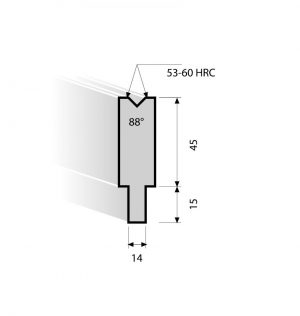

| Tool section: square | mm (in) | 20 x 20 (0.79 x 0.79) |

| Tool section: bar (diameter) | mm (in) | 25 (0.98) |

| Axial driven tool holder | DIN 6499 | |

| Radial driven tool holder | DIN 6499 | |

| Speed range (driven tool) | rpm | |

| Driven tool motor (S3 – 40% – 10 min. rating) | hp/ kW | |

| Index time: next tool (incl. clamp and unclamp) | s | |

| Index time: 180° | s | |

| Tailstock | ||

| Body travel | mm (in) | |

| Quill travel | mm (in) | |

| Quill diameter | mm (in) | |

| Body positioning | ||

| Quill activation | ||

| Quill taper hale | CM | |

| lnstalled power | ||

| Main motor AC | hp/ kW | 15/11 (S3-15 min) |

| Total installed power | kVA | 20 |

| Dimension and weight (approx,) | ||

| Floor space required (front x side) | m (in) | 3.50 x 1.57 (138 x 62) |

| Net weight (approx ) | kg (lbs) | 3,200 (7,000) |