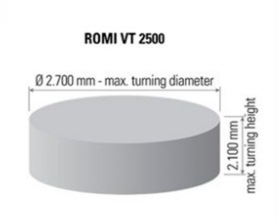

1- ROMI VT 2500M

Vertical turning machines from line ROMI VT, equipped with CNC SIEMENS, have rough mechanical structure, offering stiffness, stability and flexibility for machining processes of several type of parts for large size chuck, such as those employed by the sectors of: oil & gas, ethanol, naval, energy power generation, mining and other from base industry, they can be customized according the machining needs for which they are intended.

The Dual Drive driving system on main motorizing assures, beyond a high capacity for material removal, more accuracy and smoothness on drilling and milling operations with axis C.

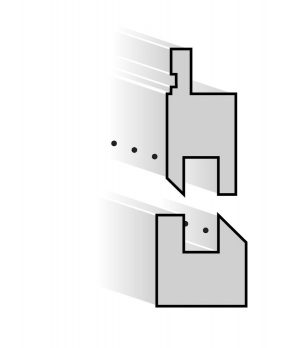

The innovative system of jaw assembly on chuck assures more stiffness and decreases the setup time of the machine.