Description

- FSCUT® CNC 22″ SCREEN FSCUT5000 TwinCAT Control System

- YASKAWA® Highly Dynamic EtherCAT Servo Drive

- RAYTOOLS ® Auto Focus Cutting Head (Switzerland)

- ACCURL® Dynamic Pipe Surface Height Tracking

- ACCURL® Fast piercing 2.0: Ultra-fast piercing

- Pipe treatment range: 15 mm - 200 mm

- ACCURL® Automatic Calibration

- Graphite anti-burn technology

- Smoke extraction system (TODC-4L/4500m³/h).

- IPG 2kW YLS-2000K Fiber Laser Resonator

- Floating servo table support system

- ATL-60 Automatic Mechanical Loading System

- CE standards: protective measures with real-time surveillance camera

- Class IV security system and CE marking

- Fully automatic voltage regulator system

- FSCCUT® Embedded PCs: Industrial PCs with directly integrated I/O level

- Industry 4.0 for sheet metal working with TwinCAT Analytics and TwinCAT IoT

Simply effective

Taking the example of a bent connection, laser cutting of tubes is 49% faster and 31% more cost-effective per piece.

- Construction, programming, work processing

- Intermediate handling, retouching

- Hourly rates

- Total time per game

- Cost per piece

Rational structure

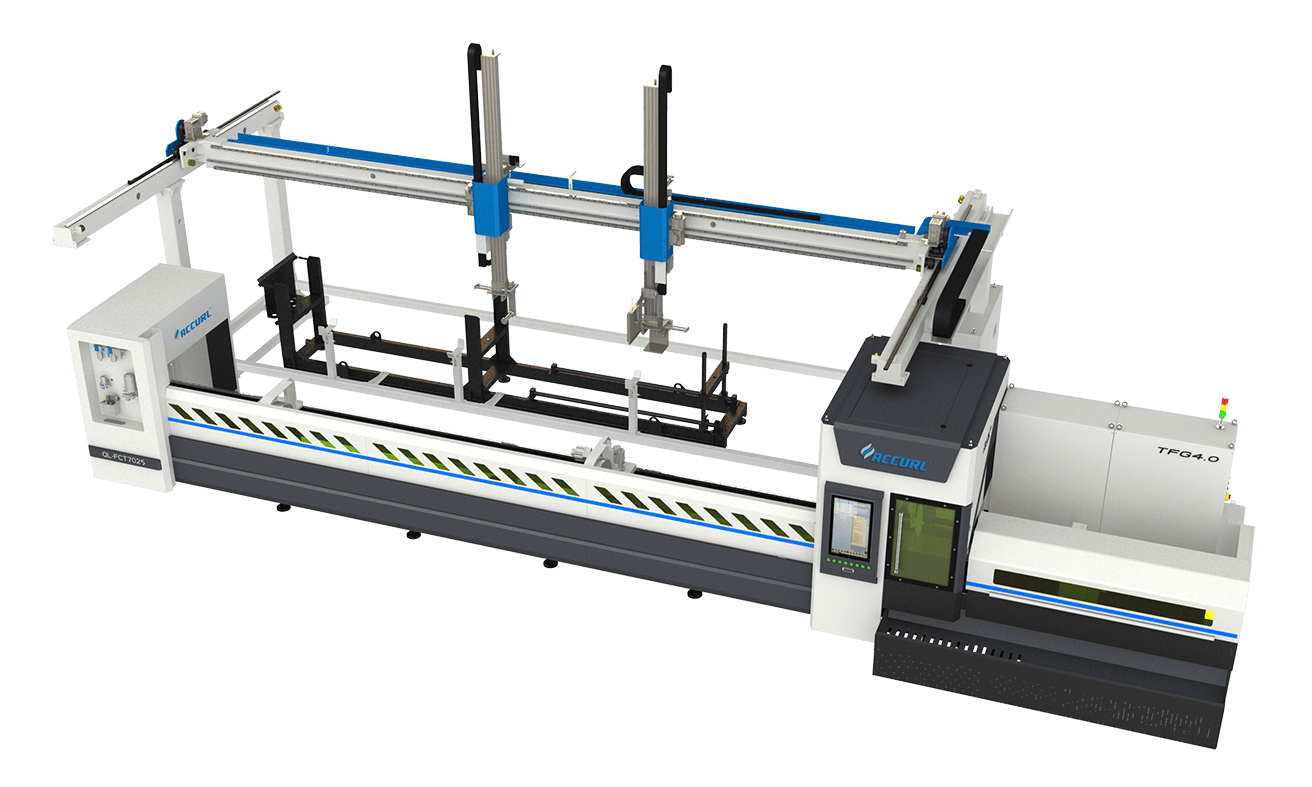

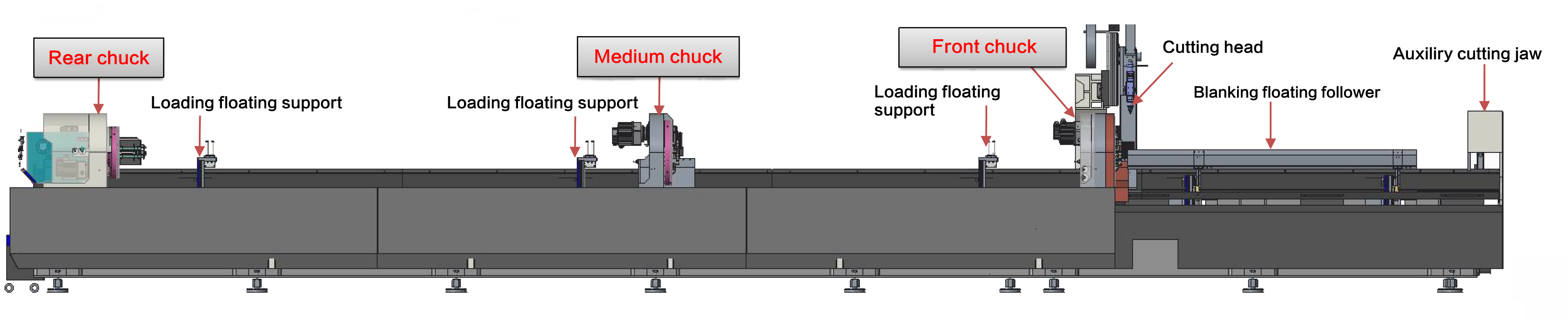

The ACCURL® QL-FCT. The 6020B tube laser offers a full range of material capabilities up to 550 mm in diameter, with raw material lengths up to 12 meters.

Atl-60 Automatic Mechanical Loading System

- Height Limit Module

Automatically distinguishes the long and short sides of the rectangular tube to ensure that each rectangular tube is laid flat and facing forward. - material frame module

and load the entire pipe bundle into the material frame. - Length measurement module

: Controls the positioning of the pipe to the desired length and transfers the data to the host. - Loading Size:

The material loading range includes oval tubes and round pipes φ 25-120 mm, and square pipes 25-120 mm. It can load a single pipe weighing 120 kg. The first loading time is 70 seconds or less; subsequent loading times are 20 seconds or less.