Description

| PARAMETERS | UNIT | UNIT |

| Electric motor | kw rpm | 5.5 KW Power (7.5 HP) at 1400 r.p.m. |

| Electricity supply | V three-phase | 230/400 |

| Electricity consumption | A | 22/12 |

| Adjustable working speed | meters per minute | 0 – 10 |

| Maximum capacity on square tube | mm | 60×60 |

| Maximum capacity on solid square block | mm | 20×20 |

| Maximum capacity on plates | mm | 60×10 |

Characteristics :

- Tempered gear transmission.

- Heavy duty roller bearings: Indispensable to guarantee the robustness and durability of the embossing machine.

- Tempered and ground shafts.

- Upper and lower shafts motorised, indispensable for good operation.

- Includes a straightening device with adjustable 7 rollers, 3 vertical and 4 horizontal. This mechanism ensures the material comes out perfectly straight.

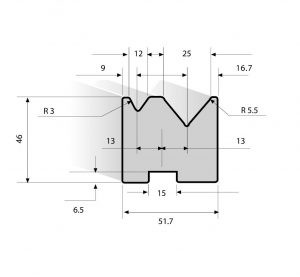

- Large catalogue of rollers of different designs (See optional accessories at the bottom of the page. At the client’s request, we can manufacture tailor made moulds, increasing the value of the finished product with exclusivity and personalization.

Lower bench palletized to easily transport the machine to the workplace or store it in case of lacking space.

Palet made of steel and 3 layer cardboard box suitable for seafreight.

Optional: Fumigated wooden box NIMF15.

Advantages :

- Ease of use: Any worker can do the job; no training is necessary.

- Highly efficient production: Thousands of components can be made in a single working day.

- No surplus material: The design of the machine enables the surface of the material to be completely embossed, so there is no loss of material.

- Value and exclusivity: All the work with a design is exclusive and adds economic value to the components manufactured.