Description

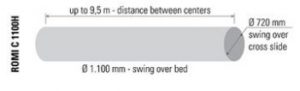

| Technical specifications | ROMI C 1100H | |

| Capacity | ||

| Centers height | mm (in) | 560 (22) |

| Distance between centers | m (in) | 2.0 (79) / 3.5 (138) / 5.0 (197) / 6.5 (256) / 8.0 (315) / 9.5 (374) |

| Swing over bed | mm (in) | 1,110 (44) |

| Swing over saddle wings | 1,055 (42) | |

| Swing in front of cross slide (short carriage) | mm (in) | |

| Swing over cross slide | mm (in) | 720 (28) |

| Cross travel (X axis) | mm (in) | 600 (24) |

| Cross travel – short (X axis) | mm (in) | |

| Longitudinal travel (Z axis) | mm (in) | 2,140 (84) / 3,665 (144) / 5,190 (204) / 6,715 (264) / 8,240 (324) / 9,765 (384) |

| Max. weight between centers at 50 rpm – ASA A2-15” (*) | kg (lbs) | |

| Max. weight between centers at 50 rpm – ASA A2-20” (*) | kg (lbs) | 15,000 (33,100) |

| Bed | ||

| Width | mm (in) | 600 (24) |

| Height | mm (in) | 490 (19) |

| Headstock | ||

| Spindle nose | ASA | A2-20” |

| Spindle thru-hole diameter | mm (in) | 375 (14,8) |

| Speed ranges (*) | rpm | 1 to 500 |

| Range I | rpm | 1 to 142 |

| Range II | rpm | 1 to 500 |

| Max. torque allowed | N.m | 12,429 |

| Front bearing inner diameter | mm (in) | 431,8 (17) |

| Feeds | ||

| Rapid traverse (Z axis) | m/min (in/min) | 8 (315) (2.0 to 3.5 m between centers lathe) / 5 (197) (5 m between centers lathe) / 10 (394) (6.5 to 9.5 m between centers lathe) |

| Rapid traverse (X axis) | m/min (in/min) | 8 (315) |

| Tailstock | ||

| Body positioning | Drag by saddle | |

| Quill drive | Manual (standard) Hydraulic (optional) | |

| Quill travel | mm (in) | 300 (11.8) |

| Quill diameter | mm (in) | 200 (7.9) |

| Live center (built-in) | metric | |

| Installed power | ||

| Main motor AC S2 – 30 min. rating (continous rating) | hp/kW | 72 / 53 |

| Total power installed | kVA | 60 |

| Dimensions and weight (approx.) (**) | 2.0 m (79) between centers lathe | |

| Floor space (front x side) | m (in) | 6.87 x 4.87 (270 x 192) |

| Net weight (approx.) | kg (lbs) | 18,000 (39,700) |

| (*) Other characteristics like distance between centers, maximum admissible weight beetween centers, power and rotation can be offered under request | ||

| (**) Weight increase for each 1,500 mm (59”) bed segment = 2,500 kg (5,500 lbs) (ROMI C 1100H / C 1290H) | ||