Description

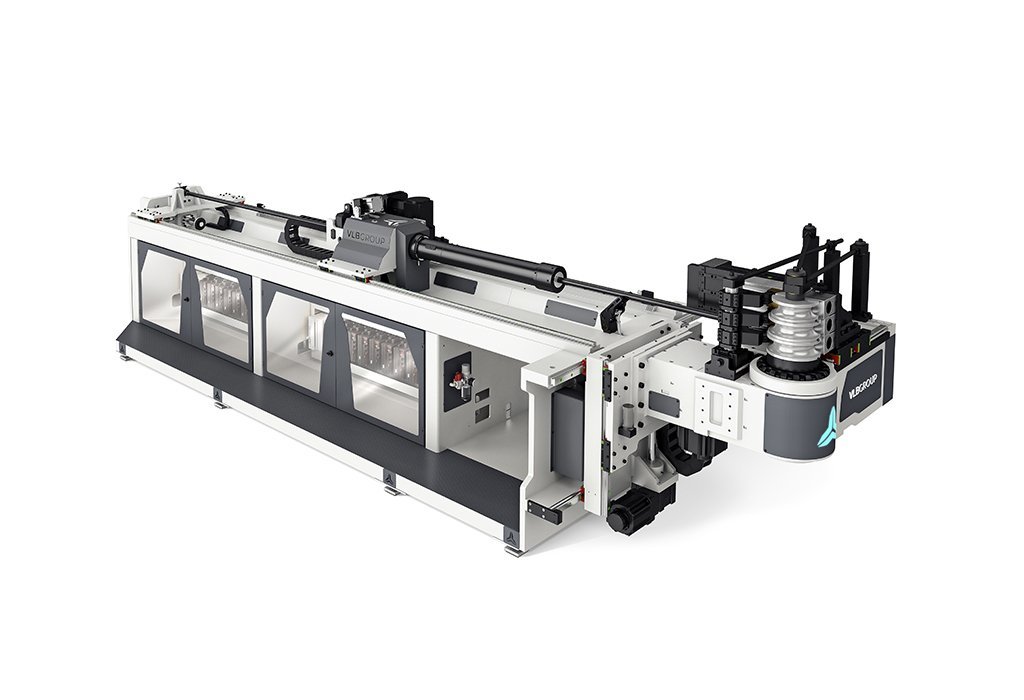

MAIN FEATURES OF FULLY ELECTRIC CNC TUBE BENDERS | EB SERIES:

100% electric drive for all 9 axles.

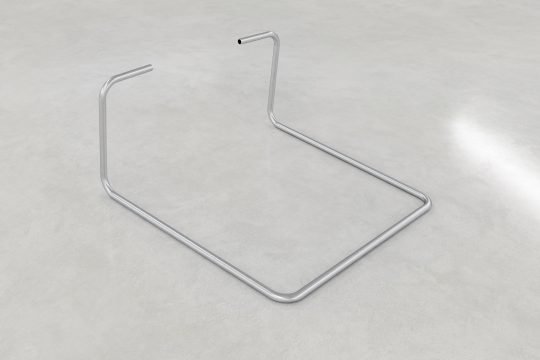

Bending of multiple fixed and variable radii in the same cycle.

Quick change of bending tool without readjustment.

High production speed and low energy consumption.

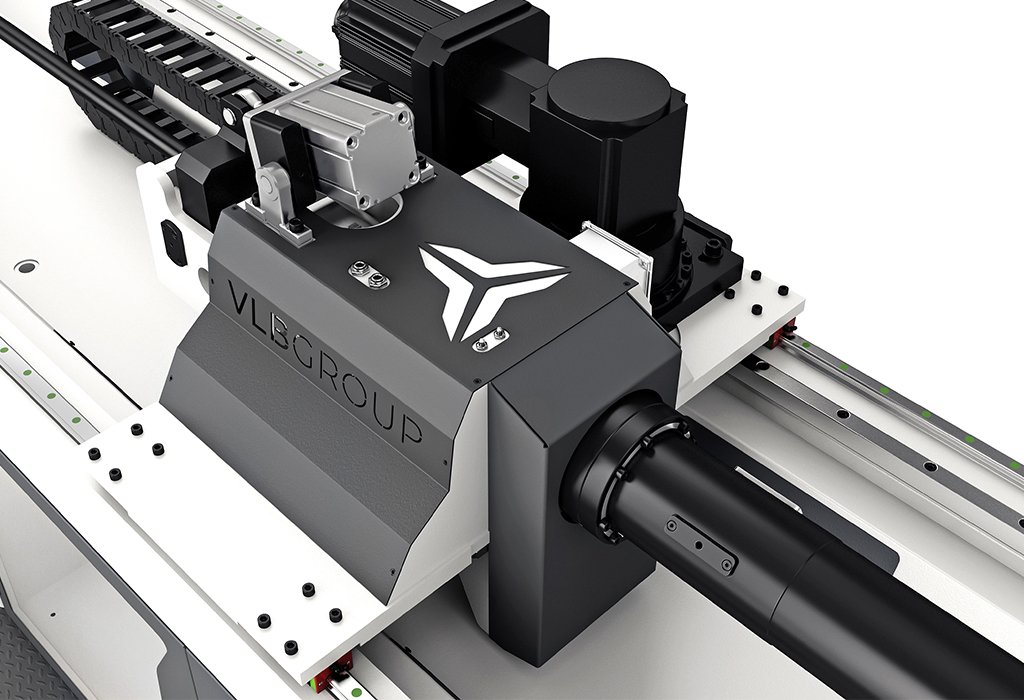

Axis movements controlled by servomotors with absolute encoder feedback.

Simplified synchronization and optimized bending cycles.

The compact and ergonomic design ensures ease of use.

Low maintenance costs with preventive maintenance alerts.

Sensors monitor the elastic behavior of the material, compensate for the bending cycle, and offer greater accuracy and less waste.

Bend to the left or right with shorter changeover times.

Powerful and intuitive VLB 3D software with anti-collision simulation.

Easily program or import files from the cloud or network.

Weld detectors, punching and cutting systems, and integration into production systems with loading and unloading facilities are available options for the EB series. VLB 3D software prepares these machines for Industry 4.0.

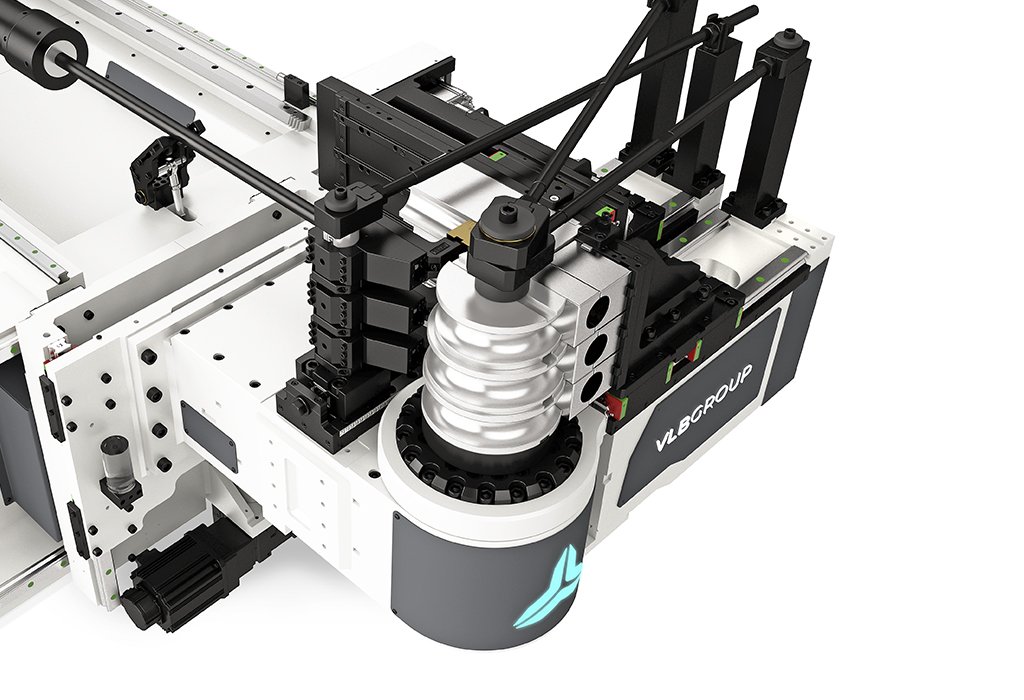

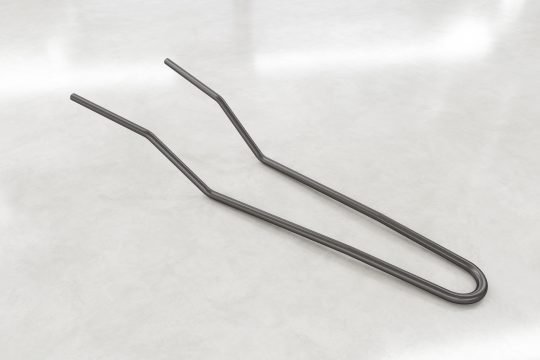

COMPACT FOLDING, RIGHT AND LEFT

The fully electric CNC tube bending machine, model EB, can be manually changed to the right and left according to customer requirements or a specific order. Both vertical and horizontal movements contribute to the wide range of motion of the bending head.

The fully electric CNC tube bending machine, model EB, can be manually changed to the right and left according to customer requirements or a specific order. Both vertical and horizontal movements contribute to the wide range of motion of the bending head.

This feature is particularly important for facilitating integration with automatic loading and unloading systems.

PIPE CUTTING SYSTEM

Production optimization is an increasingly important topic. In order to save time, materials and electricity consumption and to increase the productivity of our machines, we have developed an efficient servo-controlled cutting system that does not deform the material.

This is a cutting system with a knife integrated into the bending head. This allows cutting in a continuous automatic bending cycle without material waste, and post-processing is often unnecessary.

LOADING AND UNLOADING SYSTEMS

Aware of the needs of modern industry, new bending machines have been developed with one clear objective: productivity! They are entirely designed and prepared for

the highest level of production 24 hours a day, 7 days a week.

Mechanically, they only contain high-quality and low-maintenance components. In terms of software and hardware, they can effortlessly integrate with automatic loading and unloading systems such as tube storage, robots, or manipulators.

EVOLUTIONARY DESIGN

Our bending machines are the result of decades of experience in the world of bending. The user experience of thousands of customers worldwide has led to unique, application-oriented solutions for these machines.

Our bending machines are the result of decades of experience in the world of bending. The user experience of thousands of customers worldwide has led to unique, application-oriented solutions for these machines.

We facilitate "communication" between humans and machines using visual status indicators and warning messages. We improve operational comfort, preventive maintenance and corrective actions, and increase the safety of both the operator and the equipment.